Understanding the Role of Camshafts Manufacturers in the Diesel Engine Industry

In the world of automotive engineering, the significance of camshafts manufacturers cannot be overstated, especially when it comes to diesel engines. These components are essential for controlling the timing of valve openings and closings, which directly influences engine performance, efficiency, and emissions. This article will explore the intricate details surrounding camshafts, the manufacturing process, and how to choose the right supplier for your diesel engine parts needs.

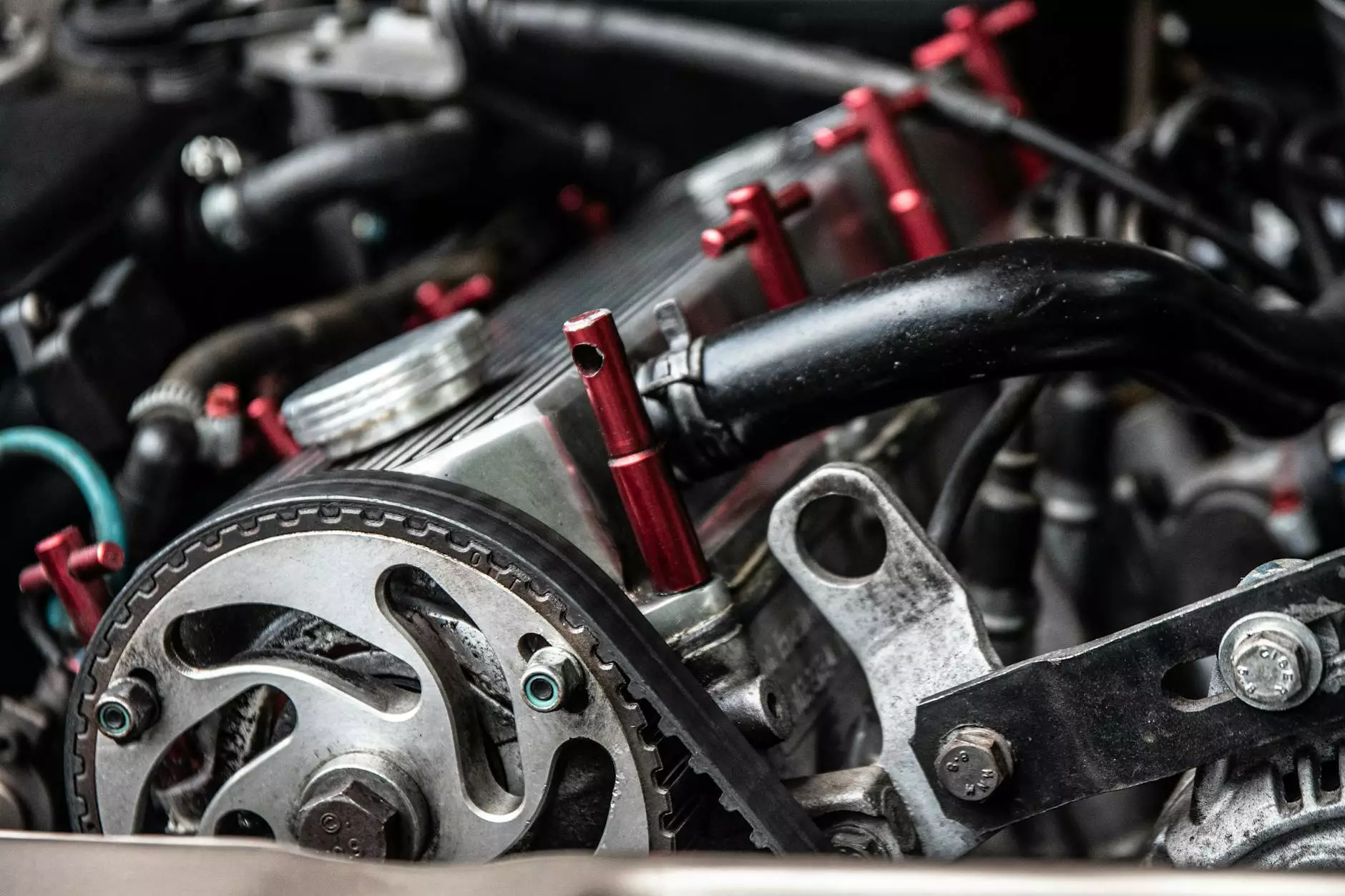

What Are Camshafts?

A camshaft is a critical component of internal combustion engines. It plays a vital role in the timing of the engine's valves. The camshaft rotates and pushes on the engine's valves through a series of lobes, allowing for precise control over intake and exhaust timings. During operation, the camshaft orchestrates various engine functions, which is crucial for maximizing performance and minimizing emissions.

The Importance of Camshafts in Diesel Engines

Diesel engines operate differently compared to gasoline engines. They rely on the principles of compression ignition, which requires a well-timed intake of air and fuel. This is where the role of camshafts becomes paramount. A high-quality camshaft ensures optimal performance in several ways:

- Improved Efficiency: A precisely manufactured camshaft can optimize the air-fuel ratio, leading to better fuel efficiency.

- Enhanced Performance: The right camshaft can increase an engine's horsepower and torque output.

- Reduced Emissions: Efficient timing reduces unburned fuel, lowering harmful emissions.

- Longevity: Durable camshafts contribute to the overall longevity of the engine by ensuring all components function smoothly.

Types of Camshafts

Camshafts come in various forms, each suited to a specific application. Understanding these types is essential when selecting parts for diesel engines.

1. Solid Camshafts

Solid camshafts are primarily used in high-performance applications. They provide greater stability and can handle high RPMs effectively.

2. Hydraulic Camshafts

Hydraulic camshafts utilize oil pressure to adjust the valve lift and duration, offering benefits in both performance and noise reduction.

3. VVT (Variable Valve Timing) Camshafts

VVT camshafts can alter their timing based on engine conditions, optimizing performance across various speeds and loads.

How Camshafts Are Manufactured

The manufacturing process of camshafts is intricate and requires precision engineering. Here are the critical stages of camshaft production:

1. Material Selection

High-quality camshafts are usually made from materials such as forged steel or high-grade aluminum to ensure durability and resilience under the high-stress conditions of an engine.

2. Machining

The selected material undergoes machining to shape the camshaft. This process is crucial as it determines the accuracy of the cam profiles.

3. Hardening

Post-machining, the camshaft is subjected to hardening processes such as heat treatment to enhance its wear resistance.

4. Finishing

Finally, the camshaft is polished and inspected to meet the strict tolerances required for optimal engine performance.

Choosing the Right Camshafts Manufacturers

When it comes to sourcing your camshafts, choosing a reputable manufacturer is critical. Here are factors to consider:

1. Experience and Expertise

Look for companies with a long history in manufacturing diesel engine parts. Experienced manufacturers are likely to produce higher quality components.

2. Quality Assurance

Ensure that the manufacturer has a robust quality control system. This includes rigorous testing of materials and finished products before they reach the market.

3. Technological Advancements

Modern manufacturing processes involving CNC machining and advanced metallurgy are crucial for the production of effective and efficient camshafts.

4. Supplier Relationships

A manufacturer with solid relationships with suppliers will often have better access to high-quality materials, impacting the final product’s quality.

5. Customer Feedback

Research customer reviews and feedback about the manufacturer. This will provide insights into their reliability and product quality.

Significance of Camshafts in Emerging Trends

With the automotive industry steadily progressing towards greener technology, the emphasis on effective camshaft design becomes more apparent. Here are emerging trends:

- Electrification: As more manufacturers pivot towards hybrid and electric engines, camshafts are being redesigned for optimal performance.

- Smart Engine Technologies: The integration of electronics in engine management systems requires more advanced camshaft designs.

- Lightweight Materials: The push for fuel efficiency is increasing the use of lightweight materials in camshaft design.

The Future of Camshafts in Diesel Engines

The future looks promising for camshafts manufacturers, driven by continuous innovations and changes within both industry standards and environmental regulations. As the demands for efficiency and performance increase, advancements in camshaft technology will play a crucial role in meeting those challenges.

Conclusion

In summary, the landscape of camshafts in the diesel engine parts market is dynamic and filled with opportunities for growth and innovation. The manufacturing quality of camshafts contributes significantly to engine efficiency, performance, and longevity. As the demand for advanced diesel technology continues to escalate, working with reputable spare parts suppliers who understand the complexities of engine dynamics will be vital. By choosing the right camshafts manufacturers, you can ensure that your diesel engines operate at peak performance for years to come.

For high-quality camshafts and diesel engine parts, consider exploring the offerings at client-diesel.com. Their commitment to excellence and customer satisfaction makes them a leading choice in the market.